Plastic Additive Manufacturing (Plastic AM) designates several processes to transform this material class.

NB : 3D printing is a Plastic AM process among others ; it is nos synonymous with “additive manufacturing” according to the industrial and academic consensus.

VOLUM-e’s mother company invests in building Plastic AM production capacity since 1993. The processes were first used for rapid prototyping.

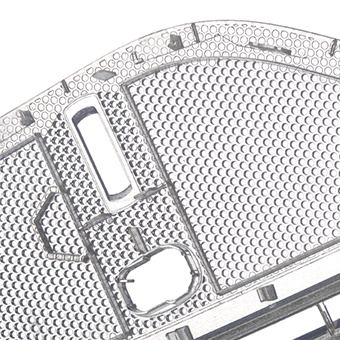

VOLUM-e focuses on turning the most industrial and performant Plastic AM processes into key resources. After specializing in the most accurate process of stereolithography (SLA), VOLUM-e has adopted the most productive technology as well : selective laser sintering (SLS).