Stereolithography (SLA) is the first modern additive manufacturing process to have been invented. It was patented in 1984.

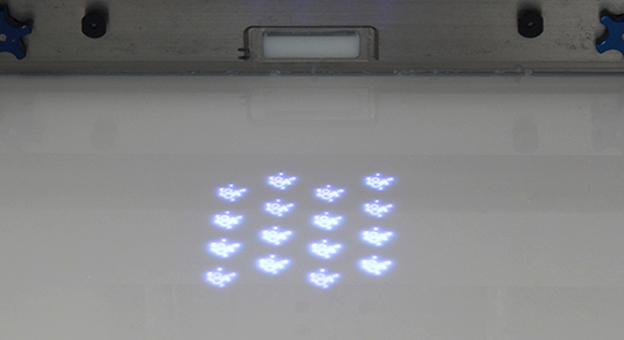

The SLA technology creates objects from digital models through selective layer-by-layer photopolymerization of a liquid resin.

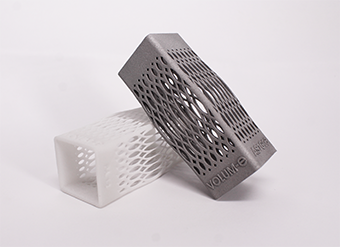

In general, SLA is more expensive than other Plastic AM processes, and the parts are less resistant and durable. Nevertheless, SLA is very accurate and yields great surface finish.

SLA is thus ideal for rapid prototyping, for direct production of aesthetic parts, or for casting patterns used in foundry or vacuum casting.