Contrôle dimensionnel et santé matière

Métrologie dimensionnelle

MMB VOLUM-e assure un contrôle dimensionnel rigoureux de ses pièces métalliques et polymères à plusieurs étapes clés du processus de production, conformément à la gamme de fabrication définie :

- Contrôle des outillages avant fabrication : vérification de la planéité des plateaux de fabrication additive métallique (FAM), précision des maîtres-modèles, etc.

- Contrôle des pièces brutes issues du procédé FAM ou après fusion.

- Contrôle des pièces métalliques après traitements thermiques (TTH) ou Hot Isostatic Pressing (HIP).

- Contrôle des pièces finies après reprise par usinage.

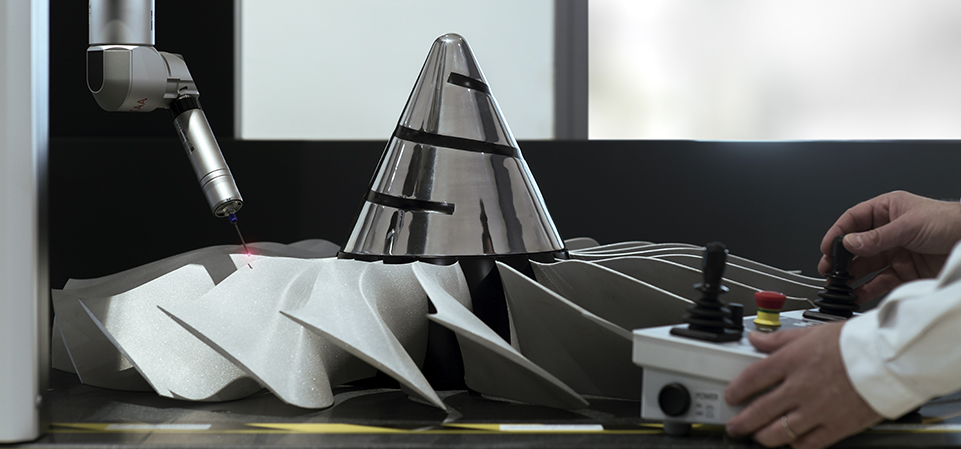

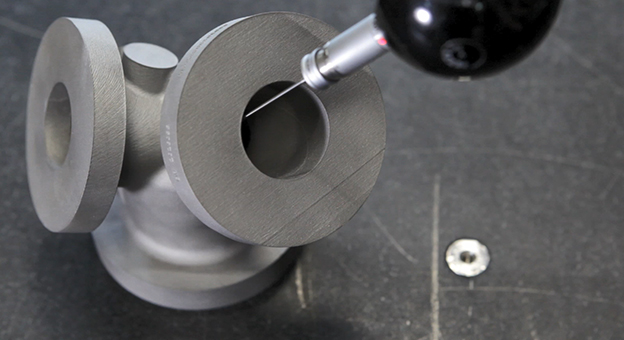

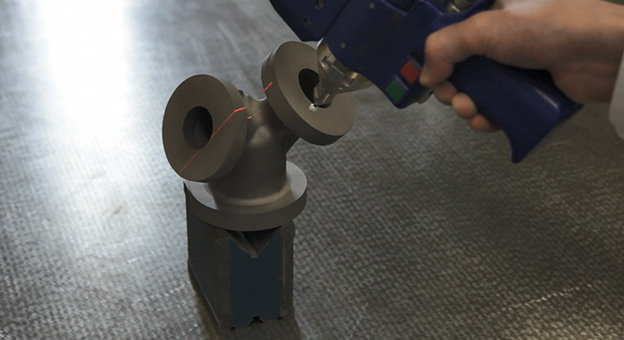

Les opérateurs qualifiés de MMB VOLUM-e maîtrisent principalement deux procédés de métrologie dimensionnelle avancée :

- Machine à Mesurer Tridimensionnelle (MMT) : La ZEISS CONTURA effectue des mesures ponctuelles avec une haute précision (tolérance longueur : E0 = 1,5 + L/350 µm) sur un volume maximal de 1000 x 1200 x 600 mm. Les données mesurées sont comparées au fichier CAO CATPART de la pièce théorique.

- Scan 3D : Le triple scan ATOS GOM capture l’intégralité de la surface de la pièce pour générer un modèle 3D STL. La comparaison avec la pièce théorique permet d’identifier rapidement les défauts dimensionnels, les déformations ainsi que les microfissures de surface. Ce procédé rapide et précis couvre des pièces de dimensions comprises entre 170x170x170 mm et 700x700x700 mm.

Contrôle métallurgique et santé matière

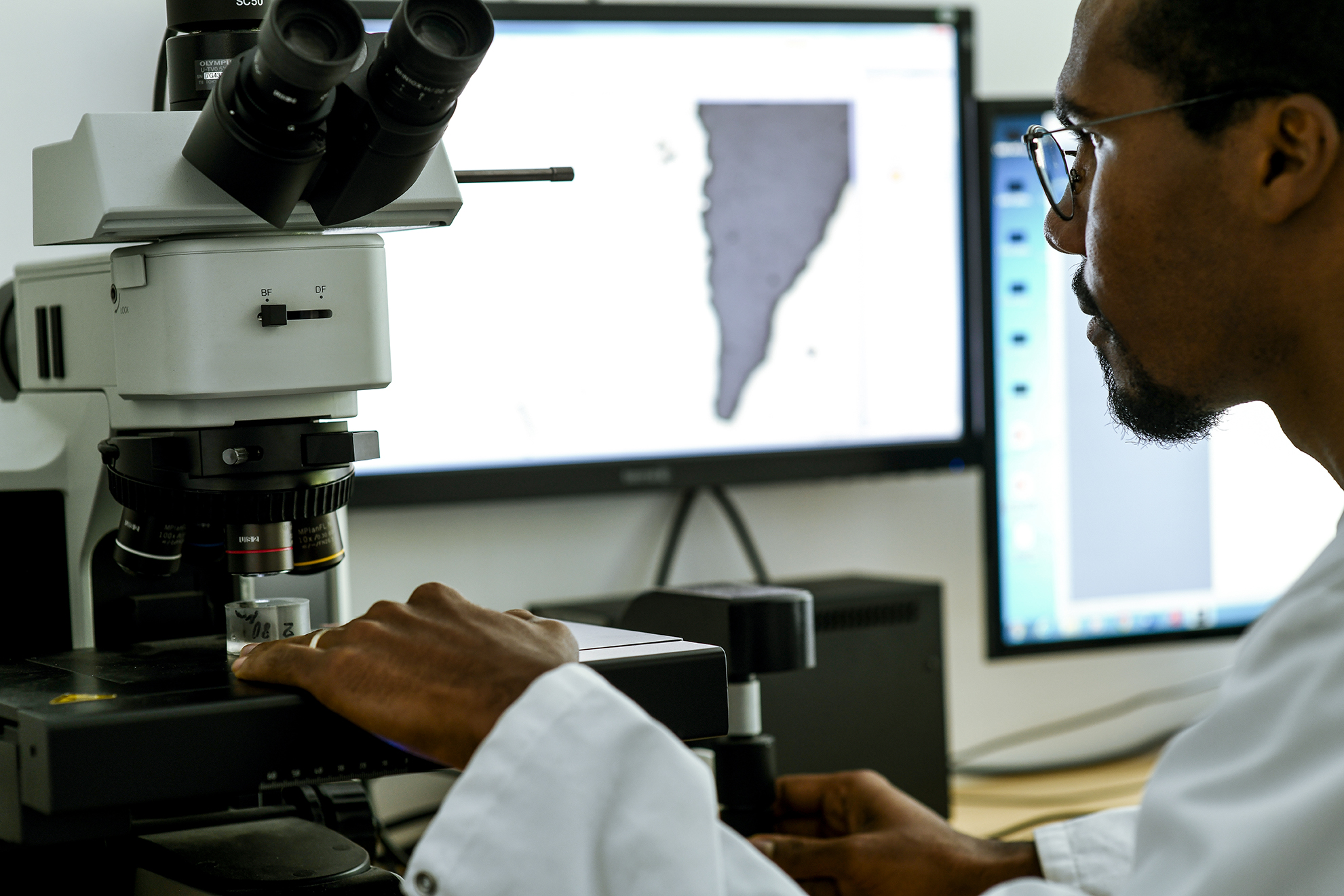

MMB VOLUM-e intègre des experts métallurgiques dédiés à la fabrication additive métal, garantissant ainsi la maîtrise complète des contrôles de santé matière. Ces contrôles sont réalisés soit par des laboratoires indépendants et qualifiés, soit en interne pour les analyses optiques. Ils sont proposés aux clients dans le cadre de projets de pièces série en fabrication additive métal (fusion laser sur lit de poudre).

Contrôle des poudres métalliques

- Caractérisation physique : vérification des caractéristiques géométriques des poudres (taille moyenne, distribution granulométrique, sphéricité).

- Analyse chimique : contrôle indépendant de la composition élémentaire des poudres.

Contrôle sur éprouvettes réalisées en parallèle (contrôle destructif)

- Porosité : mesure quantitative du volume de porosité et estimation de la taille maximale des pores.

- Métallographie : analyse de la microstructure par microscope optique sur des coupes métallographiques.

- Caractérisation mécanique : essais destructifs pour déterminer les propriétés mécaniques telles que l’allongement à la rupture (A%), la limite d’élasticité (Re), la résistance à la traction (Rm), la résistance à la fatigue, etc.

Contrôle non destructif sur pièces finies

- Radiographie industrielle : détection des fissures internes et macroporosités, particulièrement pour les parois fines, par rayons X ou Gamma.

- Contrôle par ressuage : détection de fissures de surface via des liquides pénétrants fluorescents ou colorés.

Note : Cette liste des contrôles de santé matière n’est pas exhaustive et peut être adaptée selon les exigences spécifiques des projets clients.