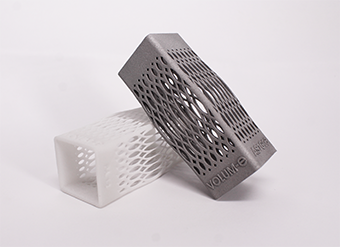

Vacuum casting consists in thermoplastic polyurethane (TPU or TPUR ) parts by the chemical reaction of polyol and isocyanate cast in silicon molds.

The results of vacuum casting much depend on the quality of the silicon mold, itself crafted from a master-model most often processed with additive manufacturing. Silicon molds are relatively inexpensive and rapidly crafted, yet, each of them can only be used under good conditions about 25 times.

Mechanical, thermal and aesthetic properties of TPU parts processed with vacuum casting are diverse and equivalent to those processed with injection molding. The vacuum casting technology for producing parts in small and medium series.