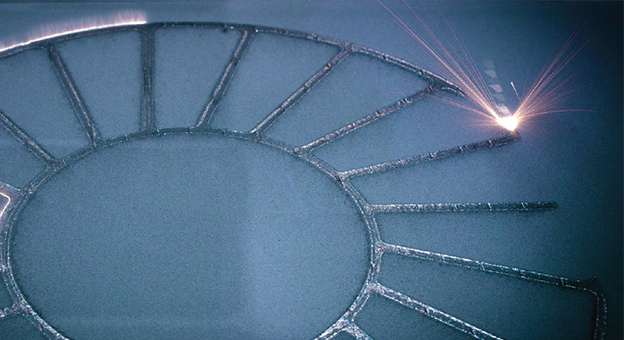

Since 2003, VOLUM-e has chosen to make a single metal additive manufacturing technology its specialty : Laser Beam Melting on Powder-Bed (LBM-PB). This choice has proven to be right because this technology is now the most accurate, precise and mature of Metal AM processes and therefore best suited for series production.

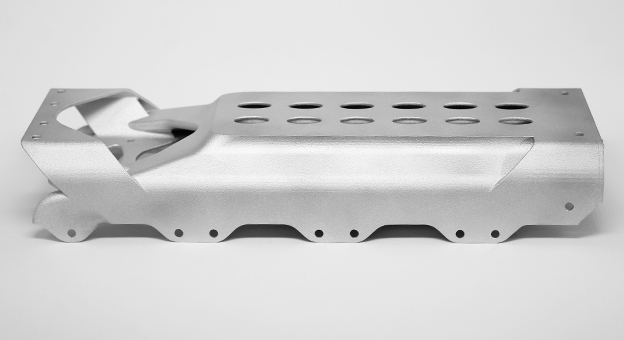

VOLUM-e owns and operates 13 LBM-PB machines, so it has among the largest capacity in France. The majority of machines can be dedicated to a single material family (9 in February 2018). This allows to effectively mitigate contamination risks and to increase productivity. These dedicated machines are referred to as “production” as they are most likely to qualify for series production.

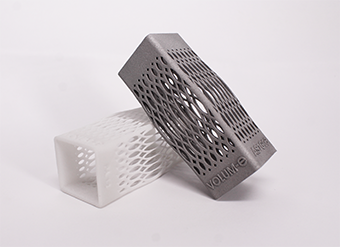

VOLUM-e allows for material switching on a minority of systems (4 in February 2018) in order to carry R&D activities, whether for internal, institutional or Customer projects.