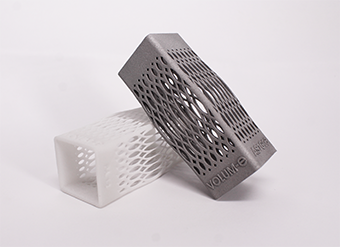

Selective laser sintering (SLS) is the second Plastic AM process mastered at VOLUM-e.

SLS creates objects from digital models through selective layer-by-layer sintering (partial fusion) of thermoplastic powder (polyamide or polystyrene in most cases) in a heated tray.

In general, SLS is less costly, more productive (in particular since it avoids building support structures) and produces more durable and resistant parts than any other Plastic AM process. Nevertheless, parts often present a rugged surface and some distortion.

SLS is ideal for rapid prototyping or for small- to medium-series production of complex parts that must resist thermal or mechanical stress. Besides, the process is well suited for making model parts used in foundry.